Pre-Use Checks and Periodic Examination

WARNING!

| • | Examine all components of connecting subsystems used with the MSA Rope THLL according to the manufacturer instructions. |

| • | Perform inspections more frequently in corrosive or extreme weather environments. |

| • | The MSA Rope THLL shall not be altered or added to. No unauthorized repairs, modifications, alterations and/or additions are permitted. |

| • | If the MSA Rope THLL is damaged or has been subjected to fall arrest forces or impact forces, it must be immediately removed from service and tagged “UNUSABLE” until it has been destroyed and disposed of in accordance with local regulations. |

| • | Vertical force applied to the lifeline may be indicated by elongation of the energy absorber. In more extreme cases, the white sections of tear webbing will become visible from the hook end of the energy absorber case. It is difficult to determine how much energy absorption remains in a partially deployed unit. Immediately remove the THLL from service and mark it as “UNUSABLE” until it has been destroyed and disposed of in accordance with local regulations. |

| • | Should any doubt arise about its condition for safe use the MSA Rope THLL shall be withdrawn from use immediately and not used again until confirmed in writing by a competent person that it is acceptable to do so. |

Failure to follow these warnings can result in serious personal injury or death.

|

Pre-Installation Checks shall occur before each installation of the MSA Rope THLL to ensure the THLL is in suitable condition for use. See Table 1 Pre-Installation Checks for examinations that must be completed before installation. |

|

Pre-Use Checks shall occur after the THLL has been installed and before each time a user connects to the THLL. The safety of the user relies upon the continued efficiency and durability of the equipment. See Table 2 Pre-Use Checks for pre-use check information. |

|

Periodic Examinations shall be completed by a person, other than the user, competent in the examination of THLLs, in accordance with the manufacturer’s instructions. The interval will be dictated by the usage, local regulations, and environmental conditions, and will be at least annually. See Table 3 Periodic Examination Interval and Section Periodic Examination Checklist for more information. A record shall be kept of the results of the examination. |

Table 1 Pre-Installation Checks

| Component | Method | |

|---|---|---|

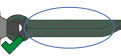

| Tensioner Cam and Drum | Inspect tensioner cam and drum for dirt ingress or stiff movement. |

|

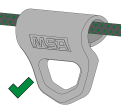

| Connectors |

Check for correct operation of connector and connector gate. |

|

| Component | Method | |

|---|---|---|

| Labels | Ensure labels are present and legible. | |

| Examination Date | Ensure date of next examination has not elapsed. Ensure a periodic examination is not due as determined by a competent person. See table below for examination interval. | |

| Load Indicator | Ensure load indicator has not been deployed by examining for white tear webbing protruding from energy absorber cover (indicates excessive force applied). |

|

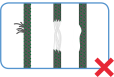

| General Condition and Lifeline |

Inspect for tears, cuts, signs of chemical damage, crushing, excessive soiling, or heavy contamination ingress. No white kern fabric should be visible through the woven black and green mantle along the length of the lifeline. |

|

| Energy Absorber Connection Points | Ensure there is no fraying, abrasion, damaged stitching, stiffness, melting, chemical attack or excessive soiling. |

|

| Hardware Elements | Examine for cracks, sharp edges, deformation, corrosion, chemical attack, excessive heating or excessive wear. |

|

| Sewn Termination | Ensure there is no fraying, abrasion, damaged stitching, stiffness, melting, chemical attack or excessive soiling. |

|

| Steel Anchor Slings (optional) | If using steel anchor slings, inspect for severe kinking, missing thimbles, broken strands, or damaged swages. | |

Table 3 Periodic Examination Interval

MSA recommends that the product is directly marked with the date of the next or last Periodic Inspection.

| Usage | Interval |

|---|---|

| Infrequent to light | Annually (12 months) |

| Moderate to heavy | Semi-annually to annually (6-12 months) |

| Severe to continuous | Quarterly to semi-annually (3-6 months) |

|

Usage shall be determined by a competent person. A competent person is defined as a person, other than the user, competent in the examination of PPE in accordance with MSA instructions. |

|