Pre-Use Checks and Periodic Examinations

The safety of the user relies upon the continued efficiency and durability of the equipment, therefore pre-use checks shall be completed before each use. See Table 1 Pre-Use Checks, for pre-use check information. Periodic examinations shall be completed by a person, other than the user, competent in the examination of PFLs, in accordance with the manufacturer’s instructions. The interval will be dictated by the usage, local regulations, and environmental conditions, and will be at least annually (see Table 2 Periodic Examination Interval). A record shall be kept of the results of the examination.

| Pre-Use Checks | Method |

|---|---|

| Labels | Ensure labels are present and legible. |

| Examination Date | Ensure date of next examination has not elapsed. Ensure a periodic examination is not due as determined by a competent person. See Table 3, Periodic Examination Interval, and product’s inspection grid. |

| General Condition and Lifeline (Web PFLs Only) | Examine for signs of excessive damage, wear, corrosion or contamination. Inspect the full length of lifeline and verify that it has no broken, frayed, cut, abraded, or missing threads. Verify there are no reductions in width or thickness of the lifeline. Verify there are no smooth, discolored, shiny, hardened, or glazed areas of the lifeline that indicate exposure to heat or chemicals. |

| For arc-flash versions, Check the webbing for any discoloration before use of the product. Discoloration could be an indication of degradation and a reduction in strength. | |

| General Condition and Lifeline (Cable PFLs Only) | Examine for signs of excessive damage, wear, corrosion or contamination. Inspect entire length of lifeline for kinks, bends, broken wires, bird caging, corrosion, damaged splices or damaged thimbles. Damage to the cable can significantly impact the performance. Verify there are no reductions in diameter of the lifeline. |

| Energy Absorber Housing (Standard Web or Cable PFLs) | Ensure that the energy absorber is not protruding from the top, bottom, or sides of the housing. Check the housing connection points for signs of parting or cracking. Inspect for the ingress of harmful chemicals or materials. |

| Energy Absorber Pouch (Arc-Flash PFLs) | Check energy absorber pouch and zip tie for signs of cuts, abrasion, fraying/broken strands, tears, burns, mold, discoloration or chemical damage |

| Extraction and Retraction | Inspect lifeline extraction and retraction by pulling the full length of the line out and letting it retract back into the housing in a controlled manner. Maintain a light tension on the lifeline while it retracts. The line operation must be smooth and unhesitant. |

| Lock-on |

Pull enough lifeline out of the unit to grip the lifeline. Pull sharply on the lifeline - ensure device locks. Repeat three times. Do not grip the energy absorber cover or connector when completing this lock-on test |

| Connectors | Check for correct operation of connector and connector gate. |

Table 2 Periodic Examination Interval

| Usage | Interval |

|---|---|

| Infrequent to light | Annually (12 months) |

| Moderate to heavy | Semi-annually to annually (6-12 months) |

| Severe to continuous | Quarterly to semi-annually (3-6 months) |

|

Usage shall be determined by a competent person. A competent person is defined as a person, other than the user, competent in the examination of PPE in accordance with MSA instructions. |

|

The V-TEC PFL is not repairable. Validity of the product: 10 years. Maximum product life: Continued use is dependent upon passing pre-use checks and periodic examinations. Service life may be reduced by frequency and conditions of use or local regulations.

WARNING!

- PFLs shall not be altered or added to. No unauthorized repairs, modifications, alterations and/or additions are permitted.

- PFLs that have arrested a fall or are unable to pass an inspection shall be tagged “UNUSABLE” and disposed of in accordance with local regulations.

- Due to the nature of some fall arrest events, it is possible for the load indicator to not deploy. In the event that a PFL is subjected to fall arrest forces and the energy absorber does not deploy, the PFL still must be removed from service and marked as “UNUSABLE” until it has been destroyed.

- If the energy absorber is deployed, immediately remove the PFL from service and mark it as “UNUSABLE” until it has been destroyed.

-

Arc-Flash PFLs exposed to an arc-flash must be removed from service and marked as "UNUSABLE" until it has been destroyed.

Failure to follow these warnings can result in serious personal injury or death.

Inspection Checklist

| Model Number: | Serial Number: | ||

| Date: | Inspector (Name / Signature): | ||

| Date of Manufacture: | Date of Purchase: | ||

| Date of First Use: | Date Due for Next Periodic Inspection: |

| # | Description | Good—Safe for Use | Good—Safe for Use | Good—Safe for Use | Damaged, Worn, Altered, Missing—Remove from Service | Comments |

| 1 | Housing | |||||

| 2 | Labels | |||||

| 3 | Lifeline | |||||

| 4 | Energy absorber | |||||

| 5 | Connectors | |||||

| Lock on (ensure device locks) |

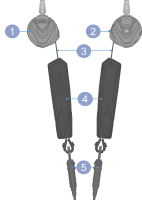

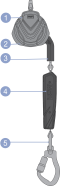

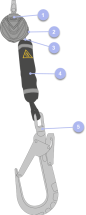

| V-TEC Web PFL | V-TEC Cable PFL | V-TEC Arc Flash PFL |

|

|

|

Hazards

Chemical hazards, heat and corrosion may damage the PFL. More frequent formal inspections are required in environments with chemical hazards, heat and corrosion. Use caution when working around moving machinery.

WARNING!

| • | Use caution when working around moving machinery. Chemical hazards, heat, and corrosion may damage the PFL. Any chemical exposure should be avoided, if possible. All chemical hazards should be accounted for prior to beginning work. |

| • | More frequent formal inspections are required in environments with chemical hazards, heat, and corrosion. As with all chemical exposures, consult the safety officer for review and recommendations for decontamination. Cleaning is strongly suggested - reference specific product cleaning guidance. |

| • | Prior to use, the end user is responsible for testing the product in the environment and conditions in which it will be used. |

Failure to follow these warnings can result in serious personal injury or death.

The below chart should only be used as general guidance for product selection and does not indicate all possible chemical exposures in the environment. Resistance ratings in the chart are determined for the materials relative to each other.

| Chemical | Resistance | |||

|---|---|---|---|---|

| Nylon | Polyester | Stainless Steel (304) | Galvanized Steel | |

| Strong acid (dilute) | Poor | Good | Fair | Poor |

| Strong acid (conc.) | Poor | Fair* | Poor | Poor |

| Weak acid (dilute) | Poor | Good | Good | Poor |

| Weak acid (conc.) | Poor | Good | Poor | Poor |

| Strong alkali (dilute) | Good | Poor | Good | Poor |

| Strong alkali (conc.) | Fair | Poor | Fair | Poor |

| Weak alkali (dilute) | Good | Fair | Good | Fair |

| Weak alkali (conc.) | Good | Poor | Fair | Poor |

| Alcohol | Good | Fair | Good | Good |

| Aldehyde | Good | Poor | Good | Good |

| Ether | Good | Poor | Good | Good |

| Halogenated Hydrocarbons | Good | Good | Good | Good |

| Phenols | Poor | Poor | Good | Good |

| Bleaching agents | Poor | Good | Fair | Poor |

| Ketones | Good | Poor | Good | Fair |

| Lubricating Oils & Greases | Good | Good | Good | Good |

| Soaps & Detergents | Good | Good | Good | Good |

| Seawater | Good | Good | Fair | Poor |

| Aromatic Solvents | Good | Poor | Good | Good |

| * Concentrated sulfuric acid attacks polyester. | ||||