Calibration

WARNING!

| • | Make sure the device has been receiving power for at least 2 hours before performing a calibration. |

| • | Make sure to remove the cap from the exhaust port before operating the device. Failure to do so will create back pressure that can result in inaccurate readings and damage to internal components. |

| • | Do NOT do calibration with a constant-flow calibration gas regulator. Use only a demand-flow type regulator (MSA P/N 710269). Failure to follow this warning can result in incorrect calibration, damage to internal components, and inaccurate gas readings. |

| • | If the device does not pass calibration, remove it from service until the issue resulting in failed calibration is corrected and a successful calibration is achieved. |

Failure to follow these warnings can result in serious personal injury or death.

NOTE: During the calibration process, the device is not monitoring for gas.

Calibration is the process of applying a known quantity of gas to the device so it can adjust the precision and accuracy of the measurements made during routine operating modes. This process ensures that gas measurements are as accurate as possible.

Although the Chillgard 5000 sensor is factory calibrated, it is recommended that calibration be performed at initial startup and at regular intervals to ensure that the sensor is fully functional and improve the accuracy of the device. Calibration accuracy is dependent on the type of cylinder used. For optimal performance, calibrate with atmospheric background for given application.

There are two types of calibration: zero gas calibration and span gas calibration.

Zero gas calibration resets the baseline level reading to zero. Use the zero-gas scrubber with ambient air for zero calibration.

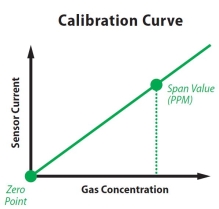

Span gas calibration applies a known concentration of target gas so the accuracy and precision of the detector can be adjusted to the known value. The known concentration of gas is called a "span value" because it represents the span, or reach, of the calibration curve from zero to that value (Figure 14

The device sensor of the Chillgard 5000 is factory calibrated with R134A, R404A, R410A, R123, R514A, R1233zd(E). The sensor also has an extended pre-programmed library of additional refrigerant gases that can be used to set up the device to detect other targeted refrigerant gases which are listed in Gas Reading Accuracy.

The Chillgard Ammonia monitor is factory calibrated with Ammonia ONLY. No R-gas library is available for the Chillgard Ammonia unit.